Roller chains have become the backbone of numerous industries when it comes to efficiently transmitting power in a variety of machinery. From bicycles and motorcycles to industrial machinery and even escalators, roller chains play a vital role in transferring power from one component to another. In this blog, we explore the fascinating world of roller chains and learn how they efficiently transmit power.

Basic structure of roller chain:

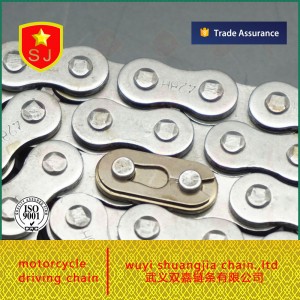

Before diving into the intricacies of power transmission, we first understand the basic structure of a roller chain. Roller chains consist of a series of interconnected links, each link consisting of inner plates, outer plates, pins and rollers. These components work in harmony to efficiently transfer power from one sprocket to the other.

Power transmission process:

When the roller chain meshes with both sprockets, power can be transferred from the driving sprocket to the driven sprocket. The drive sprocket is connected to a power source, such as an engine or electric motor, to move the chain. As the chain moves, the rollers rotate, engaging the teeth of the sprocket.

The secret of roller chain efficiency:

One of the key factors contributing to the efficiency of a roller chain is its unique design. The interaction between the rollers and sprocket teeth minimizes friction during power transmission. This design allows the rollers to spin freely while engaging the sprocket, reducing energy loss and maximizing power transfer.

Lubrication: the lifeline of roller chains:

Proper lubrication ensures the longevity and smooth operation of roller chains. Applying lubricant to the chain reduces friction, heat and wear on the components. It also helps prevent corrosion, which can significantly reduce a chain’s effectiveness over time. Regular lubrication maintenance is essential for optimal power transmission and long chain life.

Types of roller chains:

Different applications require different types of roller chains. These variations exist in size, pitch, strength and material. For example, heavy industrial machinery may use larger, stronger roller chains, while light-duty applications such as bicycles and motorcycles use smaller chains. It is critical to select the correct type of roller chain for the specific requirements of the machinery.

Factors affecting power transmission:

Several factors affect the efficiency of power transmission in roller chains. Sprocket alignment, chain tension, and overall maintenance play a vital role in ensuring smooth and reliable power transmission. Misalignment or excessive tension increases friction, causing premature wear and reduced efficiency. Regular inspections and proper maintenance can resolve these issues and optimize power delivery.

in conclusion:

In conclusion, roller chains are a reliable and efficient method of power transmission. Their unique design and ability to transmit power over long distances make them indispensable in various industries. Understanding how roller chains work and maintaining them is essential to ensure their optimal performance and longevity. So, the next time you look at a bicycle chain or observe heavy machinery in action, you’ll appreciate the wonders of power transmission with roller chains.

Post time: Jul-12-2023