Roller Chains: The Invisible Cornerstone of Agricultural Modernization

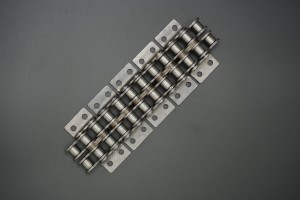

When discussing agricultural development, attention often focuses on conspicuous agricultural equipment like large harvesters and intelligent irrigation systems, but few pay attention to the seemingly ordinary roller chains within their transmission systems. In fact, from field cultivation to grain processing, from livestock breeding to agricultural product transportation, roller chains, with their stable and reliable transmission performance, have become the invisible link that ensures the efficient operation of the entire agricultural industry chain. Their intangible value is profoundly impacting agricultural production efficiency, cost control, and sustainable development.

1. Ensuring Production Continuity: A Core Barrier to Reducing “Hidden Losses” in Agriculture

Agricultural production is highly seasonal and time-sensitive. A sudden equipment failure can result in missed planting seasons, delayed harvest seasons, and ultimately irreversible economic losses. As a core transmission component in agricultural machinery, roller chains, with their low failure rate, are a key barrier to ensuring production continuity.

In major wheat-producing regions, critical components such as the header and threshing drum of combine harvesters rely on roller chains for transmission. High-quality roller chains are made of high-strength alloy steel and undergo a heat-treatment process to withstand the impact loads and constant friction of harvesting operations. Data shows that harvesters equipped with high-quality roller chains have an average trouble-free operating time of over 800 hours, a 40% increase compared to standard chains. However, during the corn harvest season, some farms suffer chain breakage due to the use of inferior roller chains. This not only requires 2-3 days of downtime for component replacement, but also increases corn losses by approximately 15% per acre due to lodging and mildew. This “no failures create value” attribute makes roller chains a hidden contributor to reducing “hidden losses” in agriculture.

In livestock farming, the continuous operation of automated feeding systems and manure removal equipment also relies on roller chains. Large-scale farms’ feeders make dozens of round trips daily, and the wear resistance of roller chains directly determines the frequency of equipment maintenance. A comparative study conducted by an intensive pig farm found that conventional roller chains required replacement every three months on average. Each maintenance stoppage resulted in feeding delays, impacting the pigs’ growth cycle. Switching to high-precision roller chains extended their service life to 18 months, reducing maintenance costs by 60,000 yuan annually while also avoiding losses caused by untimely feeding.

II. Improving Transmission Efficiency: The Invisible Power Enabling “Precision” and “Scale” in Agriculture

The core of agricultural modernization is “efficiency improvement,” and the transmission efficiency of roller chains is directly related to the operational precision and scalability of agricultural machinery. Compared to the slippage and high cost of belt drives, the “fixed-ratio transmission” characteristics of roller chains enable agricultural equipment to precisely execute operational instructions, providing fundamental support for precision agriculture and large-scale production.

During the sowing process, the seed meter of a precision seeder is connected to the power system via a roller chain. The chain’s transmission error must be controlled within 0.5% to ensure uniform plant spacing and consistent sowing depth. A no-till seed drill developed by an agricultural technology company uses a customized roller chain, improving seeding accuracy from ±3 cm to ±1 cm. This reduces seeding error per acre by 8%. This not only saves seed costs but also increases yield per acre by approximately 5% due to improved crop uniformity. This “millimeter-level” precision improvement directly reflects the intangible value of roller chains.

For large-scale farms, the power transmission efficiency of large agricultural machinery determines the operating radius and production capacity. Tractor-driven rotary tillers, deep plows, and other equipment use roller chains to convert engine power into operational power. High-quality roller chains can achieve transmission efficiencies exceeding 98%, while inefficient chains result in increased power loss and fuel consumption of 10%-15%. For example, a 150-horsepower tractor equipped with a high-efficiency roller chain can cover an additional 30 acres per day. Assuming a per-acre operating income of 80 yuan, this can generate nearly 100,000 yuan in additional value per operating season.

III. Extending Equipment Lifecycles: Long-Term Support for Optimizing Agricultural Cost Structures

Agricultural equipment is a critical fixed asset on farms, and its service life directly impacts the long-term costs of agricultural production. The durability and adaptability of roller chains not only reduce the frequency of equipment replacement but also reduce wear on associated components through stable transmission, thereby extending the lifecycle of the entire equipment and achieving the long-term value of “cost reduction and efficiency improvement.”

In grain processing, the roller drive systems of flour mills, rice mills, and other equipment rely on the stable operation of roller chains. Inadequate meshing precision of inferior chains can lead to unstable roller operation, exacerbating wear on bearings, gears, and other components, shortening the overall equipment life by 30%. Roller chains using a carburizing and quenching process, on the other hand, not only extend their lifespan to over five years but also reduce the frequency of associated component replacement, reducing equipment maintenance costs by 40%. A medium-sized flour mill has demonstrated that simply by replacing high-quality roller chains, they can save 80,000 to 100,000 yuan in annual equipment maintenance costs and extend the equipment’s depreciation period from 8 to 12 years.

Furthermore, the versatility of roller chains facilitates cost control in agriculture. Roller chains of the same specifications can be used with different brands and models of agricultural machinery, reducing spare parts inventory pressure on farms. For farms in remote areas, insufficient spare parts are often the biggest challenge following equipment failures. The versatility of roller chains allows farms to stock only a small number of core specifications to handle emergency repairs for a wide range of equipment, reducing inventory capital and storage costs.

IV. Promoting Agricultural Machinery Upgrades: The Underlying Logic of Supporting Sustainable Agricultural Development

As global agriculture shifts toward green, efficient, and sustainable practices, the requirements for transmission components in new agricultural equipment are becoming increasingly stringent. The technological evolution of roller chains is providing the underlying support for agricultural machinery upgrades and driving changes in agricultural production methods.

In the field of new energy agricultural machinery, new equipment such as electric tractors and solar irrigation equipment place even higher demands on low noise and low energy consumption in their transmission systems. By optimizing the chain plate structure and using silent lubricating grease, traditional roller chains can reduce noise to below 65 decibels and energy consumption by 5%, making them a perfect fit for the needs of new energy agricultural machinery. An electric harvester developed by a certain company, equipped with a silent roller chain, not only meets noise standards for farmland operations but also reduces energy consumption, extending operating time by 1.5 hours on a single charge, further improving operational efficiency.

In the field of ecological agriculture, the corrosion resistance of roller chains facilitates the adoption of environmentally friendly agricultural machinery. Rice transplanters and crop protection machines used in rice fields are exposed to humid and dusty environments for extended periods, where conventional chains are prone to rust and failure. However, roller chains made of stainless steel or with surface coatings can withstand acid and alkali corrosion and immersion in muddy water, extending their service life by more than two times. This not only reduces waste generated by chain replacements but also minimizes soil and water pollution from agricultural machinery operations, aligning with the development of ecological agriculture.

Furthermore, the modular design of roller chains facilitates intelligent upgrades for agricultural machinery. By integrating sensors into the chain, parameters such as transmission system tension and temperature can be monitored in real time, transmitting this data to the machinery’s intelligent control system, enabling predictive maintenance. When chain wear warnings appear, the system can proactively alert operators to replace the chain, avoiding production interruptions caused by sudden failures. This combination of “intelligence + reliable transmission” is becoming a crucial component of smart agriculture.

How to Choose: Realizing the “Intangible Value” of Roller Chains

For agricultural operators, choosing the right roller chain is a prerequisite for realizing its intangible value. When purchasing, focus on three key indicators: First, “Material and Craftsmanship.” Prefer products made from high-strength steels such as 40Cr and 20Mn2, which undergo through-hardening and roller carburizing. Second, “Precision Grade.” Agricultural machinery recommends using chains with ISO Grade 6 or higher precision to ensure stable transmission. Third, “Compatibility.” Choose a pitch and roller diameter that matches the power, speed, and operating environment of the agricultural machinery. Customization is available if necessary.

Regular maintenance is also crucial. During daily use, clean the chain of dirt and debris promptly and apply special lubricant regularly to prevent accelerated wear caused by dry friction. Simple maintenance measures can extend the lifespan of roller chains by an additional 30%, further amplifying their intangible value.

Conclusion: Invisible Value Supports a Sustainable Future

Roller chains lack the roar of a harvester or the glitz of intelligent systems, yet they quietly permeate every aspect of agricultural production. They ensure continuous production, improve operational efficiency, optimize cost structures, and drive agricultural upgrades. This intangible value is both the cornerstone of agricultural mechanization and the invisible engine of agricultural modernization.

Post time: Sep-12-2025