Comparison of Transmission Accuracy between Roller Chains and Toothed Chains

I. The Underlying Logic of Transmission Accuracy: Structural Differences Determine the Upper Limit of Performance

1. The Accuracy Bottleneck of Roller Chains: Polygonal Effect and Non-uniform Wear

Roller chains consist of rollers, bushings, pins, and chain plates. During meshing, power is transmitted through point contact between the rollers and the sprocket teeth. Its core precision defects stem from two points: **Polygonal effect:** The chain forms a regular polygonal structure around the sprocket. The larger the pitch P and the fewer the sprocket teeth, the more severe the instantaneous speed fluctuations (formula: v=πd₁n₁/60×1000, where d₁ is the sprocket pitch circle diameter), leading to an unstable transmission ratio. **Uneven wear:** After hinge wear, the outer link pitch increases significantly while the inner link maintains its original size, creating a pitch difference that accelerates precision decay.

2. Precision advantages of toothed chains: Involute meshing and uniform elongation. Toothed chains (also known as silent chains) are hinged from staggered toothed chain plates. Line contact meshing is achieved through the chain plate tooth profile and the involute tooth profile of the sprocket: **Multi-tooth meshing characteristics:** Overlap ratio reaches 2-3 (roller chains only…). 1.2-1.5), distributing load while ensuring transmission continuity. Uniform wear design: The overall elongation of each chain link is consistent after wear, with no local pitch deviation, resulting in better long-term accuracy retention. Optimized guide structure: The internal guide design avoids lateral movement, and the parallelism error control between the two shafts is more precise.

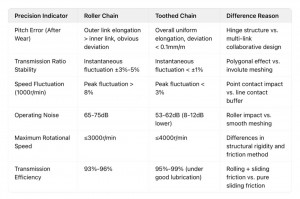

II. Quantitative Comparison of Core Transmission Accuracy Indicators

III. Key External Factors Affecting Transmission Accuracy

1. Sensitivity to Installation Accuracy: Toothed chains have extremely high requirements for the parallelism of the two shafts (error ≤ 0.3mm/m), otherwise it will exacerbate chain plate wear and cause a sharp drop in accuracy. Roller chains allow for larger installation errors (≤ 0.5mm/m), adapting to coarse positioning scenarios under harsh working conditions.

2. The Influence of Load and Speed: Low-speed heavy load (<500rpm): The accuracy difference between the two is reduced, and roller chains are more economical due to their cost advantage. High-speed precision (>2000rpm): The polygon effect suppression advantage of toothed chains is prominent, and the accuracy decay rate is only 1/3 that of roller chains.

3. The Importance of Lubrication and Maintenance in Precision Maintenance: Roller chains experience 3-5 times faster wear when lacking lubrication, and pitch error increases exponentially. Toothed chains require regular cleaning and lubrication to maintain the precision of the sliding friction surfaces, resulting in higher maintenance costs than roller chains.

IV. Scenario-Based Selection Guide: Precision Requirements Take Priority Over Cost Considerations

1. Toothed Chain Application Scenarios:

High-speed precision equipment: Engine timing transmission, precision machine tool spindle drive (speed > 3000 r/min)

Low-noise environments: Textile machinery, medical devices (noise requirement < 60dB)

Heavy-load smooth transmission: Mining machinery, metallurgical equipment (torque > 1000 N·m)

2. Roller Chain Application Scenarios:

General machinery: Agricultural machinery, logistics conveyor lines (low speed, heavy load, precision requirement ±5%)

Harsh environments: Dust/humid conditions (simple structure, strong anti-pollution ability)

Cost-sensitive projects: The cost of a single-row roller chain is only a fraction of that of a toothed chain of the same specifications. 40%-60%

V. Summary: The Art of Balancing Precision and Practicality

The essence of transmission precision is a comprehensive result of structural design, material processing, and adaptation to operating conditions: Toothed chains achieve high precision and high stability through complex structures, but incur higher manufacturing costs and installation requirements; Roller chains sacrifice some precision for versatility, low cost, and ease of maintenance. When selecting a model, core requirements should be prioritized: When the transmission ratio error requirement is <±1%, the speed is >2000 r/min, or noise control is strict, toothed chains are the optimal solution; if the operating conditions are harsh, the budget is limited, and the precision tolerance is high, roller chains remain a reliable choice for industry.

Post time: Nov-24-2025