Ungayijonga njani kwaye uyitshintshe njani igrisi yeeroller chains rhoqo?

Ukuthambisa iiroller chain kubalulekile ekugcineni ukusebenza kwazo nokwandisa ubomi bazo benkonzo. Nazi amanyathelo aneenkcukacha kunye neengcebiso zokujonga rhoqo nokutshintsha igrisi yeeroller chain.

1. Jonga rhoqo imeko yokuthambisa

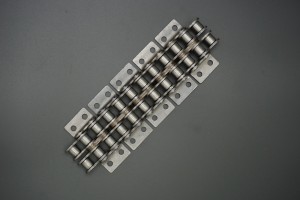

Ukuhlolwa kwenkangeleko: Ngaphambi kokuba uqalise umatshini yonke imihla, qala ujonge inkangeleko ye-roller chain coupling ukuqinisekisa ukuba akukho zimpawu zomonakalo, ukuguquka okanye ukubola. Kwangaxeshanye, qwalasela uxinzelelo lwe-chain ukuqinisekisa ukuba ayiqini kakhulu ukuba ingandisa ukuguguleka okanye ayikhululekanga kakhulu ukuba ingabangela ukutsiba kwe-chain.

Imeko yokuthambisa: Jonga iindawo zokuthambisa ukuqinisekisa ukuba igrisi yanele kwaye icocekile. Faka isixa esifanelekileyo segrisi kwi-roller chain rhoqo ukunciphisa ukungqubana nokunciphisa ilahleko. Qaphela ukuba ukhetho lwegrisi kufuneka luhambelane neemeko zokusebenza kwaye uphephe ukuxuba iintlobo ezahlukeneyo.

Isandi sokusebenza: Emva kokuqalisa izixhobo, phulaphula ngononophelo isandi sokusebenza se-roller chain coupling. Ingxolo engaqhelekanga idla ngokuba luphawu lwempazamo, njengeengxaki ze-chain kunye ne-sprocket meshing, umonakalo weebheringi, njl.njl., ekufuneka zihlolwe ngexesha.

2. Ukucoca kunye nokucoca ungcoliseko

Itsheyini yeroli kufuneka icocwe kwaye isuswe ukungcola rhoqo, kwaye isiphumo sokuthambisa kufuneka sijongwe rhoqo. Coca itsheyini ngesepha ethambileyo kunye nebrashi ethambileyo ukuze ususe uthuli kunye negrisi endala. Eli nyathelo libalulekile ukuqinisekisa ukuba igrisi isasazwa ngokulinganayo kuzo zonke iindawo zetsheyini.

3. Jonga isiphumo sokuthambisa

Emva kokucoca, jonga isiphumo sokuthambisa setsheyini. Ukuba umphezulu wokungqubana umdaka okanye umdaka omnyama, oku kuthetha ukuba akukho mbane owaneleyo kunye nokuthambisa okungekho semgangathweni. Kwimeko enjalo, igrisi kufuneka itshintshwe.

4. Khetha igrisi efanelekileyo

Kubalulekile ukukhetha igrisi efanelekileyo kwiimeko zokusebenza. Igrisi yokulwa nomhlwa esetyenziswa kwezinye iiroller chain inefuthe lokulwa nomhlwa kunye nokuthambisa kwaye yimveliso yegrisi ebiza kakhulu. Ingathintela ngempumelelo ukungqubana kwinqanaba lokuqala lokusebenza kwaye iqinisekise ukudibana kwetsheyini kunye negrisi ukuphucula ukumelana nokungqubana.

5. Buyisela igrisi

Ukongeza indawo yeoyile: Ukolula kokungqubana kwerola yentsimbi kudla ngokuvela phakathi kwephini yetsheyini kunye ne-bushing, ngoko ke yongeza ioyile kule ndawo. Xa ufaka ioyile yokuthambisa, nceda wongeze ioyile phakathi kwepleyiti yetsheyini yangaphandle kunye nepleyiti yetsheyini yangaphakathi kwicala elikhululekileyo lerola yentsimbi. Kwangaxeshanye, kufuneka kufakwe ioyile phakathi kwesleeve kunye nerola.

Indlela yokuzalisa amafutha: Ngokuxhomekeke kwindawo yokusetyenziswa, iindlela ezahlukeneyo zokuthambisa zingakhethwa, kubandakanya ukuzalisa amafutha ngesandla, ukuthambisa ngebhafu yeoyile, ukuthambisa nge-splash kunye nokuthambisa ngepompo yeoyile enyanzelisiweyo. Indlela nganye inomlinganiselo wayo wokuzalisa amafutha kunye neemfuno zexesha elithile.

Umjikelo wokutshintsha igrisi: Misela umjikelo wokutshintsha igrisi ngokusekelwe kwiingcebiso zomenzi wezixhobo kunye neemeko zokusetyenziswa. Ngokubanzi, gcwalisa ipetroli rhoqo emva kweeyure ezisi-8 okanye ngaphezulu.

6. Uqeqesho lobuchwephesha kunye nokuxilongwa kweziphene

Ukubonelela ngoqeqesho lobuchwephesha kubaqhubi kunye nabasebenzi bokulungisa ukuphucula amandla abo okuchonga nokujongana nokusebenza kwe-roller chain coupling, iimpazamo, kunye neemeko ezingxamisekileyo. Xa bedibana neziphene ezinzima, iingcali zobuchwephesha kufuneka zimenywe ukuba zixilonge, zisebenzise izixhobo zokufumana ngokukhawuleza unobangela wengxaki, kwaye zenze isicwangciso solondolozo sesayensi nesifanelekileyo esisekelwe kwiziphumo zokuxilongwa.

7. Ukurekhoda nohlalutyo

Misela ifayile epheleleyo yerekhodi yolondolozo, urekhode ixesha, umxholo, iindawo ezitshintshiweyo kunye nemiphumo yolondolozo ngalunye ngokweenkcukacha, kwaye unike isalathiso esinamandla solondolozo olulandelayo.

Ngokulandela la manyathelo angasentla, ungaqinisekisa ukuba igrisi ye-roller chain ihlolwe kwaye ithathelwe indawo ngempumelelo, ngaloo ndlela yandisa ubomi benkonzo ye-chain kwaye igcina ukusebenza kwayo okuphezulu.

Ungayivavanya njani impembelelo yegrisi? Zeziphi izalathisi ezinokusetyenziswa njengesalathiso?

Xa uvavanya isiphumo segrisi, ungabhekisa kwezi mpawu zilandelayo ziphambili:

Ukusebenza kokulwa nokugqwala: Vavanya amandla okulwa nokugqwala kwegrisi kwiintsimbi phantsi kweemeko ezahlukeneyo zokusingqongileyo

Ukusebenza kobushushu obuphantsi: Vavanya ukugeleza kunye nokufunxwa kwegrisi kwindawo enobushushu obuphantsi

Ukusebenza kobushushu obuphezulu: Vavanya uzinzo kunye nokusebenza kokuthambisa kwegrisi kwindawo enobushushu obuphezulu

Ukumelana namanzi: Vavanya indlela igrisi ehlanjwa ngayo ngamanzi kunye nokusebenza kwayo ekulweni ne-emulsification kwindawo efumileyo

Uvavanyo lwemeko yokusebenza olulinganisiweyo: Lingisa iimeko zokusebenza zokwenyani (ezifana nobushushu, uxinzelelo, isantya, njl.njl.) kwilebhu kwaye wenze uvavanyo lokusebenza lwexesha elide

Uvavanyo lokwaluphala: Lingisa ukwaluphala kwegrisi ngexesha lokusetyenziswa ixesha elide ukuze uvavanye ubomi bayo benkonzo kunye nomjikelo wokutshintshwa kwayo

Uvavanyo lwasentsimini kunye nempendulo: Faka igrisi kwizixhobo zokwenyani, wenze uvavanyo kangangexesha elithile, kwaye uqokelele idatha yokusebenza kunye nempendulo yomsebenzisi.

Ulawulo lomgangatho kunye nesatifikethi: Sebenzisa ngokungqongqo imigangatho yolawulo lomgangatho ngexesha lenkqubo yemveliso ukuqinisekisa ukuhambelana kunye nozinzo lwebhetshi nganye yegrisi, kwaye wenze isiqinisekiso kunye novavanyo lomntu wesithathu (njenge-ISO, i-ASTM kunye neminye imigangatho) ngokwemigangatho yoshishino kunye neemfuno zabathengi.

Thixotropy: I-thixotropy yegrisi ithetha ukuba ithamba kancinci kancinci xa kusetyenziswa amandla angaphandle, kwaye i-viscosity iyancipha, kodwa inokubuyela kwimeko yayo emva kokuba ingashukumi.

Ukuqina: Ukuqina kwegrisi luphawu lokuhamba kwayo, oludla ngokubonakaliswa njengokuqina okubonakalayo okanye ukuqina okufanayo, kwaye ubushushu kunye nesantya sokucheba kufuneka kuchazwe.

Umda wamandla: Umda wamandla egrisi ubhekisa kuxinzelelo oluncinci lokucheba olufunekayo ukuze isampuli iqale ukugeleza

Ukutyibilika kobushushu obuphantsi: Esinye sezibonakaliso ezibalulekileyo zokulinganisa ukusebenza kobushushu obuphantsi kwegrisi yi-torque yobushushu obuphantsi, oko kukuthi, inqanaba apho igrisi ithintela ukujikeleza kwe-bearing yokuhamba kwesantya esiphantsi kumaqondo obushushu aphantsi.

Inqanaba lokuwa: Ubushushu obuphantsi apho igrisi ifikelela khona kulwelo oluthile phantsi kweemeko ezithile bubizwa ngokuba yinqanaba lokuwa, nto leyo enceda ekuchongeni uhlobo lwegrisi kunye nokuqikelela ubushushu obuphezulu bokusebenza.

Ukukhutshwa komoya: Ukuguquguquka kwegrisi kubonisa inqanaba lokuphuma komoya kwi-oyile yegrisi xa igrisi isetyenziswa ixesha elide phantsi kweemeko zobushushu obuphezulu.

Uzinzo lweColloid: Uzinzo lweColloidal lwegrisi lubhekisa kubuchule bayo bokugcina isakhiwo seColloidal esizinzileyo kubushushu obuthile kunye noxinzelelo ukuthintela ioyile yokuthambisa ukuba ingangeni kwigrisi.

Uzinzo lwe-oxidation: Uzinzo lwe-oxidation yegrisi lubhekisa kubuchule bayo bokumelana nemiphumo yobushushu kunye ne-oksijini ngexesha lokugcina ixesha elide okanye ukusetyenziswa ixesha elide kumaqondo obushushu aphezulu, kunye nokugcina iipropati zayo ngaphandle kotshintsho oluhlala luhleli.

Ngale miqondiso, ukusebenza kunye nefuthe legrisi kunokuvavanywa ngokupheleleyo ukuqinisekisa ukuba igrisi ekhethiweyo inokuhlangabezana neemfuno zezicelo ezithile.

Ixesha lokuthumela: Disemba-09-2024