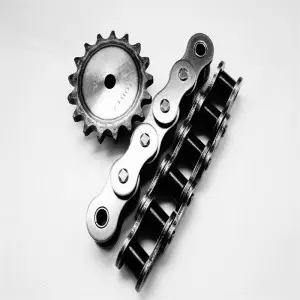

Itekhnoloji yonyango lobushushu inempembelelo ebalulekileyo kumgangatho wangaphakathi weendawo zetyathanga, ingakumbi iityathanga zebhayisekile. Ke ngoko, ukuze kuveliswe iityathanga zebhayisekile ezikumgangatho ophezulu, kufuneka itekhnoloji yonyango lobushushu oluphambili kunye nezixhobo.

Ngenxa yomahluko phakathi kwabavelisi basekhaya nabangaphandle ngokwemigaqo yokuqonda, ulawulo olukwindawo kunye neemfuno zobugcisa zomgangatho wetsheyini yeebhayisekile, kukho umahluko kwinkqubo yokwenza, yokuphucula kunye neyokuvelisa itekhnoloji yonyango lobushushu kwiindawo zetsheyini.

(1) Itekhnoloji yonyango lobushushu kunye nezixhobo ezisetyenziswa ngabavelisi basekhaya. Izixhobo zonyango lobushushu kwishishini leekhonkco zelizwe lam zisemva kwezo zamazwe aphuhlileyo kwezoshishino. Ngokukodwa, izitofu zebhanti ye-mesh zasekhaya zineengxaki ezininzi ezifana nesakhiwo, ukuthembeka kunye nozinzo.

Iipleyiti zentsimbi zangaphakathi nezangaphandle zenziwe ngeepleyiti zentsimbi ezingama-40Mn kunye nama-45Mn, kwaye ezi zinto zineziphene ezifana nokususwa kwekhabhoni kunye nokuqhekeka. Ukucima kunye nokushisa kusebenzisa isithando sebhanti esiqhelekileyo se-mesh ngaphandle konyango lokususwa kwekhabhoni, okubangela ukuba kubekho umaleko ogqithisileyo wokususwa kwekhabhoni. Iiphini, imikhono kunye neerola ziyasuswa kwaye zicinywe, ubunzulu bokuqina obusebenzayo bokucima yi-0.3-0.6mm, kwaye ubunzima bomphezulu buyi-≥82HRA. Nangona isithando se-roller sisetyenziselwa ukuvelisa okuguquguqukayo kunye nokusetyenziswa kwezixhobo eziphezulu, ukuseta iiparameter zenkqubo Useto kunye notshintsho kufuneka kwenziwe ziingcali, kwaye kwinkqubo yemveliso, la maxabiso eeparameter asetwa ngesandla awanakulungiseka ngokuzenzekelayo ngotshintsho olukhawulezileyo lomoya, kwaye umgangatho wonyango lobushushu usaxhomekeke kakhulu kwiingcali ezikwindawo (abasebenzi bezobugcisa). Inqanaba lobugcisa liphantsi kwaye ukuphinda-phinda komgangatho kuphantsi. Xa kujongwa imveliso, iinkcukacha kunye neendleko zemveliso, njl.njl., le meko kunzima ukuyitshintsha okwethutyana.

(2) Itekhnoloji yonyango lobushushu kunye nezixhobo ezisetyenziswa ngabavelisi bamanye amazwe. Iifeni zebhanti eziqhubekekayo okanye imigca yokuvelisa unyango lobushushu lwetyathanga eliphosiweyo isetyenziswa kakhulu kwamanye amazwe. Itekhnoloji yokulawula umoya ivuthiwe. Akukho mfuneko yokuba iingcali zenze le nkqubo, kwaye amaxabiso eeparameter afanelekileyo anokulungiswa nangaliphi na ixesha ngokweenguqu ezikhawulezileyo emoyeni okwisithando; ukuze kugxilwe kumaleko ofakwe i-carburized, imeko yokusasazwa kobunzima, umoya kunye nobushushu inokulawulwa ngokuzenzekelayo ngaphandle kokulungiswa ngesandla. Ixabiso lokuguquguquka koxinzelelo lwekhabhoni linokulawulwa ngaphakathi koluhlu lwe-≤0.05%, ukuguquguquka kwexabiso lobunzima kunokulawulwa ngaphakathi koluhlu lwe-1HRA, kwaye ubushushu bunokulawulwa ngokungqongqo ngaphakathi koluhlu lwe-± ngaphakathi koluhlu lwe-0.5 ukuya kwi-±1℃.

Ukongeza kumgangatho ozinzileyo wokucima nokulungisa iipleyiti zetyathanga zangaphakathi nezangaphandle, ikwanayo nokusebenza kakuhle kwemveliso. Ngexesha lokucima nokucima i-pin shaft, i-sleeve kunye ne-roller, utshintsho lwe-concentration distribution curve luhlala lubalwa ngokwexabiso lokwenyani lesampulu yobushushu besithando kunye nekhono lekhabhoni, kwaye ixabiso elibekiweyo leeparameter zenkqubo liyalungiswa kwaye liphuculwe nangaliphi na ixesha ukuqinisekisa ukuba umaleko we-carburised Umgangatho wangaphakathi uphantsi kolawulo.

Ngamafutshane, kukho umsantsa omkhulu phakathi kwenqanaba letekhnoloji yonyango lobushushu beenxalenye zeebhayisekile zelizwe lam kunye neenkampani zangaphandle, ikakhulu ngenxa yokuba inkqubo yolawulo lomgangatho kunye nesiqinisekiso ayingqongqo ngokwaneleyo, kwaye isasele emva kwamazwe aphuhlileyo, ingakumbi umahluko kwitekhnoloji yonyango lomphezulu emva konyango lobushushu. Iindlela zokufaka imibala ezilula, ezisebenzayo nezingcolisiyo kumaqondo obushushu ahlukeneyo okanye ukugcina umbala wokuqala zingasetyenziswa njengokhetho lokuqala.

Ixesha lokuthumela: Sep-08-2023