(1) Qhov sib txawv tseem ceeb ntawm cov khoom siv hlau siv rau cov khoom siv saw hlau hauv tsev thiab txawv teb chaws yog nyob rau hauv cov phaj saw hlau sab hauv thiab sab nraud. Kev ua tau zoo ntawm cov phaj saw hlau xav tau lub zog tensile siab thiab qee qhov kev tawv. Hauv Suav teb, 40Mn thiab 45Mn feem ntau yog siv rau kev tsim khoom, thiab 35 hlau tsis tshua siv. Cov tshuaj lom neeg sib xyaw ntawm 40Mn thiab 45Mn steel phaj yog dav dua li ntawm cov hlau S35C thiab SAEl035 txawv teb chaws, thiab muaj 1.5% txog 2.5% tuab decarburization ntawm qhov chaw. Yog li ntawd, cov phaj saw hlau feem ntau raug kev txom nyem los ntawm kev tawg brittle tom qab quenching thiab txaus tempering.

Thaum lub sijhawm kuaj qhov nyuaj, qhov nyuaj ntawm qhov saw hlau tom qab quenching yog qis (tsawg dua 40HRC). Yog tias qee qhov tuab ntawm txheej saum npoo raug hnav tawm, qhov nyuaj tuaj yeem ncav cuag ntau dua 50HRC, uas yuav cuam tshuam loj heev rau qhov tsawg kawg nkaus tensile load ntawm cov saw hlau.

(2) Cov chaw tsim khoom txawv teb chaws feem ntau siv S35C thiab SAEl035, thiab siv cov cub tawg carburizing uas siv cov ntxaij vab tshaus txuas ntxiv mus ntxiv. Thaum lub sijhawm kho cua sov, muaj huab cua tiv thaiv rau kev kho dua tshiab. Tsis tas li ntawd, kev tswj hwm cov txheej txheem nruj heev tau siv, yog li cov phaj saw hlau tsis tshua muaj tshwm sim. Tom qab quenching thiab tempering, brittle fracture lossis qis nto hardness tshwm sim.

Kev soj ntsuam metallographic qhia tau hais tias muaj ntau cov qauv martensite zoo li koob (kwv yees li 15-30um) ntawm qhov chaw ntawm lub phaj saw tom qab quenching, thaum lub hauv paus yog cov qauv martensite zoo li strip. Nyob rau hauv qhov xwm txheej ntawm tib lub phaj saw tuab, qhov tsawg kawg nkaus tensile load tom qab tempering yog loj dua li ntawm cov khoom hauv tsev. Hauv cov teb chaws txawv teb chaws, 1.5 hli tuab phaj feem ntau siv thiab lub zog tensile xav tau yog> 18 kN, thaum cov saw hauv tsev feem ntau siv 1.6-1.7 hli tuab phaj thiab lub zog tensile xav tau yog> 17.8 kN.

(3) Vim yog kev txhim kho tas mus li ntawm cov kev cai rau cov khoom siv maus taus, cov chaw tsim khoom hauv tsev thiab txawv teb chaws txuas ntxiv txhim kho cov hlau siv rau cov koob, tes tsho thiab cov menyuam. Qhov tsawg kawg nkaus tensile load thiab tshwj xeeb tshaj yog qhov hnav tsis kam ntawm cov saw hlau yog cuam tshuam nrog cov hlau. Tom qab cov chaw tsim khoom hauv tsev thiab txawv teb chaws tsis ntev los no xaiv 20CrMnTiH hlau ua cov khoom siv pin es tsis yog 20CrMnMo, lub zog tensile ntawm cov saw hlau nce ntxiv los ntawm 13% txog 18%, thiab cov chaw tsim khoom txawv teb chaws siv SAE8620 hlau ua cov khoom siv pin thiab tes tsho. Qhov no kuj cuam tshuam nrog qhov no. Kev xyaum tau qhia tias tsuas yog los ntawm kev txhim kho qhov sib txawv ntawm tus pin thiab tes tsho, txhim kho cov txheej txheem kho cua sov thiab lubrication, tuaj yeem ua rau hnav tsis kam thiab tensile load ntawm cov saw hlau tau zoo heev.

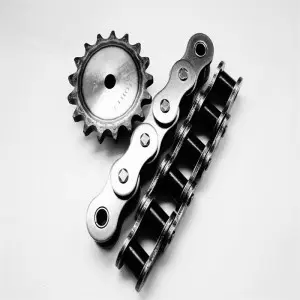

(4) Hauv cov khoom siv ntawm cov saw hlau maus taus, lub phaj txuas sab hauv thiab lub tes tsho, lub phaj txuas sab nraud thiab tus pin raug txuas ua ke nrog qhov sib haum, thaum tus pin thiab lub tes tsho yog qhov sib haum. Qhov sib haum ntawm cov khoom siv saw hlau muaj feem cuam tshuam loj rau qhov hnav tsis kam thiab qhov hnyav tsawg kawg nkaus ntawm cov saw hlau. Raws li kev siv sib txawv thiab kev puas tsuaj ntawm cov saw hlau, nws muab faib ua peb theem: A, B thiab C. Chav Kawm A yog siv rau kev sib kis hnyav, kev kub ceev thiab tseem ceeb; Chav Kawm B yog siv rau kev sib kis dav dav; Chav Kawm C yog siv rau kev hloov iav ib txwm muaj. Yog li ntawd, qhov yuav tsum tau ua kom sib koom tes ntawm cov khoom siv ntawm Chav Kawm A yog nruj dua.

Lub sijhawm tshaj tawm: Cuaj hlis-08-2023