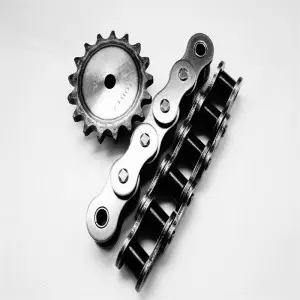

Kev siv tshuab kho cua sov muaj feem cuam tshuam loj heev rau qhov zoo ntawm cov saw hlau, tshwj xeeb yog cov saw hlau maus taus. Yog li ntawd, txhawm rau tsim cov saw hlau maus taus zoo, kev siv tshuab kho cua sov thiab cov khoom siv siab heev yog qhov tsim nyog.

Vim muaj qhov sib txawv ntawm cov tuam txhab tsim khoom hauv tsev thiab txawv teb chaws hais txog kev nkag siab, kev tswj hwm ntawm qhov chaw thiab cov kev cai ntawm cov saw hlau maus taus zoo, muaj qhov sib txawv hauv kev tsim, kev txhim kho thiab cov txheej txheem tsim khoom ntawm cov txheej txheem kho cua sov rau cov khoom siv saw.

(1) Cov thev naus laus zis kho cua sov thiab cov khoom siv siv los ntawm cov chaw tsim khoom hauv tsev. Cov khoom siv kho cua sov hauv kuv lub teb chaws txoj kev lag luam saw hlau poob qis dua li cov teb chaws tsim kev lag luam. Tshwj xeeb, cov cua sov siv mesh hauv tsev muaj ntau yam teeb meem xws li cov qauv, kev ntseeg siab thiab kev ruaj khov.

Cov phaj sab hauv thiab sab nraud yog ua los ntawm 40Mn thiab 45Mn steel phaj, thiab cov ntaub ntawv feem ntau muaj qhov tsis zoo xws li decarburization thiab tawg. Quenching thiab tempering siv cov cua sov siv mesh siv tsis muaj kev kho mob recarburization, ua rau muaj ntau txheej decarburization. Cov pins, tes tsho thiab rollers yog carburized thiab quenched, qhov tob ntawm quenching yog 0.3-0.6 hli, thiab qhov nyuaj ntawm qhov chaw yog ≥82HRA. Txawm hais tias lub cub tawg roller siv rau kev tsim khoom yooj ywm thiab kev siv cov khoom siv siab, kev teeb tsa ntawm cov txheej txheem tsis. Cov chaw teeb tsa thiab kev hloov pauv yuav tsum tau ua los ntawm cov kws tshaj lij, thiab hauv cov txheej txheem ntau lawm, cov nqi parameter teeb tsa tes no tsis tuaj yeem kho tau nrog kev hloov pauv ntawm huab cua tam sim ntawd, thiab qhov zoo ntawm kev kho cua sov tseem nyob ntawm ntau qhov ntawm cov kws tshaj lij hauv tsev (cov neeg ua haujlwm tshaj lij). Qib kev tshaj lij qis thiab qhov zoo rov ua dua tsis zoo. Xav txog cov zis, cov lus qhia thiab cov nqi tsim khoom, thiab lwm yam, qhov xwm txheej no nyuaj rau hloov pauv ib ntus.

(2) Cov thev naus laus zis kho cua sov thiab cov khoom siv tau txais los ntawm cov tuam txhab tsim khoom txawv teb chaws. Cov cua sov siv txoj siv sia lossis cov kab tsim khoom siv kho cua sov siv dav hauv txawv teb chaws. Cov thev naus laus zis tswj huab cua yog qhov paub tab heev. Tsis tas yuav tsum muaj cov kws tshaj lij los tsim cov txheej txheem, thiab cov nqi parameter cuam tshuam tuaj yeem kho tau txhua lub sijhawm raws li kev hloov pauv tam sim ntawd hauv huab cua hauv lub cub tawg; rau qhov concentration ntawm cov txheej carburized, qhov xwm txheej faib tawm ntawm qhov nyuaj, huab cua thiab kub tuaj yeem tswj tau yam tsis tas hloov kho tes. Tus nqi hloov pauv ntawm cov pa roj carbon concentration tuaj yeem tswj tau hauv qhov ntau ntawm ≤0.05%, qhov kev hloov pauv ntawm tus nqi hardness tuaj yeem tswj tau hauv qhov ntau ntawm 1HRA, thiab qhov kub tuaj yeem tswj tau nruj me ntsis hauv ± Hauv qhov ntau ntawm 0.5 txog ± 1 ℃.

Ntxiv rau qhov ruaj khov ntawm sab hauv thiab sab nraud saw phaj quenching thiab tempering, nws kuj muaj kev ua haujlwm siab. Thaum lub sijhawm carburizing thiab quenching ntawm tus pin ncej, tes tsho thiab roller, qhov kev hloov pauv ntawm cov kab sib faib concentration yog suav tas li raws li qhov tseeb sampling tus nqi ntawm lub cub tawg kub thiab carbon peev xwm, thiab tus nqi teeb tsa ntawm cov txheej txheem tsis raug kho thiab optimized txhua lub sijhawm kom ntseeg tau tias cov txheej carburized Intrinsic zoo nyob rau hauv kev tswj hwm.

Hauv ib lo lus, muaj qhov sib txawv loj ntawm kuv lub teb chaws cov khoom siv kho cua sov ntawm cov saw hlau maus taus thiab cov tuam txhab txawv teb chaws, feem ntau vim tias qhov kev tswj hwm zoo thiab kev lees paub tsis nruj txaus, thiab nws tseem poob qis dua cov teb chaws tsim, tshwj xeeb tshaj yog qhov sib txawv ntawm cov thev naus laus zis kho qhov chaw tom qab kho cua sov. Cov txheej txheem yooj yim, siv tau thiab tsis ua rau muaj kuab paug ntawm qhov kub sib txawv lossis khaws cov xim qub tuaj yeem siv ua qhov kev xaiv thawj zaug.

Lub sijhawm tshaj tawm: Cuaj hlis-08-2023