Amaketanga Okujikijela: Itshe Legumbi Elingabonakali Lokuthuthukiswa Kwezolimo

Uma kukhulunywa ngentuthuko yezolimo, ukunaka kuvame ukugxila emishinini yezolimo ebonakalayo njengemishini yokuvuna emikhulu kanye nezinhlelo zokunisela ezihlakaniphile, kodwa bambalwa abanaka okubonakala kujwayelekileamaketanga okugoqangaphakathi kwezinhlelo zabo zokudlulisa. Eqinisweni, kusukela ekulimeni ensimini kuya ekucubungulweni kokusanhlamvu, kusukela ekuzaleni imfuyo kuya ekuthuthweni kwemikhiqizo yezolimo, amaketanga okugoqa, ngokusebenza kwawo okuzinzile nokuthembekile kokudlulisa, abe yisixhumanisi esingabonakali esiqinisekisa ukusebenza kahle kochungechunge lonke lwemboni yezolimo. Inani labo elingabonakali lithinta kakhulu ukusebenza kahle komkhiqizo wezolimo, ukulawulwa kwezindleko, kanye nentuthuko esimeme.

1. Ukuqinisekisa Ukuqhubeka Kokukhiqiza: Isithiyo Esiyinhloko Ekunciphiseni “Ukulahlekelwa Okufihliwe” Kwezolimo

Ukukhiqizwa kwezolimo kuyinkinga enkulu yesizini futhi kuthinta isikhathi. Ukwehluleka kwemishini ngokuzumayo kungabangela ukungaphumeleli kwezikhathi zokutshala, ukuphuza isikhathi sokuvuna, kanye nokulahlekelwa kwezomnotho ekugcineni okungenakuguqulwa. Njengengxenye eyinhloko yokudlulisela imishini yezolimo, amaketanga okugoqa, anezinga lawo eliphansi lokwehluleka, ayisithiyo esiyinhloko ekuqinisekiseni ukuqhubeka kokukhiqiza.

Ezindaweni ezinkulu ezikhiqiza ukolweni, izingxenye ezibalulekile njenge-header kanye ne-wrailing drum yama-combine harvesters zithembele kuma-roller chain ukuze zidluliselwe. Ama-roller chain asezingeni eliphezulu enziwe ngensimbi enamandla kakhulu futhi adlula enkambisweni yokwelashwa ngokushisa ukuze amelane nemithwalo yokuthinteka kanye nokungqubuzana okuqhubekayo kwemisebenzi yokuvuna. Idatha ikhombisa ukuthi ama-roller chain ahlonyiswe ngama-roller chain asezingeni eliphezulu anesikhathi sokusebenza esingenazinkinga samahora angaphezu kuka-800, ukwanda okungu-40% uma kuqhathaniswa nama-standard chain. Kodwa-ke, ngesikhathi sokuvuna ummbila, amanye amapulazi ahlushwa ukuphuka kwama-chain ngenxa yokusetshenziswa kwama-roller chain aphansi. Lokhu akudingi nje kuphela izinsuku ezingu-2-3 zokungasebenzi ukuze kufakwe ezinye izingxenye esikhundleni sazo, kodwa futhi kwandisa ukulahlekelwa kommbila cishe ngo-15% ngehektare ngenxa yokuhlala kanye ne-moldew. Lesi sici "sokungaphumeleli okudala inani" senza ama-roller chain abe nomthelela ofihliwe ekunciphiseni "ukulahlekelwa okufihliwe" kwezolimo.

Ekulimeni kwemfuyo, ukusebenza okuqhubekayo kwezinhlelo zokudla ezenzakalelayo kanye nemishini yokususa umquba nakho kuncike ezintanjeni ezigoqayo. Izinsiza zokudla zamapulazi amakhulu zenza uhambo oluningi oluya nokubuya nsuku zonke, futhi ukumelana nokuguguleka kwezintambo ezigoqayo kunquma ngqo imvamisa yokugcinwa kwemishini. Ucwaningo oluqhathanisiwe olwenziwe yipulazi lezingulube elinamandla luthole ukuthi izintambo ezigoqayo ezivamile zazidinga ukushintshwa njalo ezinyangeni ezintathu ngokwesilinganiso. Ukumiswa ngakunye kokugcinwa kwaholela ekubambezelekeni kokudla, okuthinta umjikelezo wokukhula kwezingulube. Ukushintshela ezintanjeni ezigoqayo ezinembe kakhulu kwandise impilo yazo yenkonzo yaba yizinyanga ezingu-18, kunciphisa izindleko zokugcinwa ngama-yuan angu-60,000 ngonyaka ngenkathi kugwema nokulahlekelwa okubangelwa ukondla ngaphambi kwesikhathi.

II. Ukuthuthukisa Ukusebenza Kahle Kokudlulisa: Amandla Angabonakali Avumela “Ukunemba” kanye “Nesilinganiso” Kwezolimo

Ingqikithi yokuthuthukiswa kwezolimo “ukuthuthukiswa kokusebenza kahle,” futhi ukusebenza kahle kokudlulisela kwamaketanga okugoqa kuhlobene ngqo nokunemba kokusebenza kanye nokukhula kwemishini yezolimo. Uma kuqhathaniswa nokushelela kanye nezindleko eziphezulu zama-belt drive, izici “zokudlulisela okulinganiselwe” zamaketanga okugoqa zivumela imishini yezolimo ukuthi ikhiphe imiyalelo yokusebenza ngokunembile, inikeze ukwesekwa okuyisisekelo kwezolimo ezinembile kanye nokukhiqizwa okukhulu.

Ngesikhathi senqubo yokuhlwanyela, imitha yembewu yesithombo sokuhlwanyela ngokunemba ixhunywe ohlelweni lwamandla ngeketanga lokugoqa. Iphutha lokudlulisela leketanga kumele lilawulwe ngaphakathi kuka-0.5% ukuqinisekisa izikhala zezitshalo ezifanayo kanye nokujula kokuhlwanyela okuhambisanayo. I-drill yembewu engakavulwa eyakhiwe yinkampani yezobuchwepheshe bezolimo isebenzisa iketanga lokugoqa elenziwe ngokwezifiso, ithuthukisa ukunemba kokuhlwanyela kusuka ku-±3 cm kuya ku-±1 cm. Lokhu kunciphisa iphutha lokuhlwanyela ngehektare ngo-8%. Lokhu akugcini nje ngokusindisa izindleko zembewu kodwa futhi kwandisa isivuno ngehektare cishe ngo-5% ngenxa yokufana kwezitshalo okuthuthukisiwe. Lokhu kuthuthukiswa kokunemba "kwezinga le-millimeter" kubonisa ngqo inani elingabonakali lamaketanga okugoqa.

Kumapulazi amakhulu, ukusebenza kahle kokudlulisa amandla kwemishini emikhulu yezolimo kunquma irediyasi yokusebenza kanye nomthamo wokukhiqiza. Ama-rotary tillers aqhutshwa yi-tractor, ama-deep plow, kanye neminye imishini isebenzisa ama-roller chain ukuguqula amandla enjini abe amandla okusebenza. Ama-roller chain asezingeni eliphezulu angafinyelela ukusebenza kahle kokudlulisa amandla okudlula ama-98%, kuyilapho ama-roller chain angasebenzi kahle eholela ekulahlekelweni kwamandla okwandisiwe kanye nokusetshenziswa kukaphethiloli okungu-10%-15%. Isibonelo, i-tractor enamandla amahhashi angu-150 efakwe i-roller chain esebenza kahle kakhulu ingamboza amahektha angu-30 engeziwe ngosuku. Uma sibheka imali engenayo yokusebenza ngehektha engu-80 yuan, lokhu kungakhiqiza cishe ama-yuan ayi-100,000 ngenani elengeziwe ngesizini yokusebenza.

III. Ukwandisa Imijikelezo Yokuphila Kwemishini: Ukusekelwa Kwesikhathi Eside Kokuthuthukisa Izakhiwo Zezindleko Zezolimo

Imishini yezolimo iyimpahla ebalulekile ehlala isikhathi eside emapulazini, futhi impilo yayo yesevisi ithinta ngqo izindleko zesikhathi eside zokukhiqiza kwezolimo. Ukuqina kanye nokuzivumelanisa nezimo kwamaketanga okugoqa akugcini nje ngokunciphisa imvamisa yokushintsha imishini kodwa futhi kunciphisa ukuguguleka kwezingxenye ezihambisanayo ngokudluliselwa okuzinzile, ngaleyo ndlela kwandise umjikelezo wokuphila kwemishini yonke futhi kufezwe inani lesikhathi eside "lokunciphisa izindleko kanye nokuthuthukiswa kokusebenza kahle."

Ekucubungulweni kokusanhlamvu, izinhlelo zokushayela ama-roller zemishini yokugaya ufulawa, imishini yokugaya irayisi, kanye neminye imishini zithembele ekusebenzeni okuzinzile kwamaketanga okugaya. Ukunemba okunganele kwe-meshing kwamaketanga angaphansi kungaholela ekusebenzeni kwama-roller okungazinzile, okwandisa ukuguguleka kwama-bearings, amagiya, kanye nezinye izingxenye, kufinyeze impilo yemishini iyonke ngo-30%. Ngakolunye uhlangothi, amaketanga okugaya asebenzisa inqubo yokugaya nokucima i-carburing, awagcini nje ngokwandisa isikhathi sawo sokuphila sibe ngaphezu kweminyaka emihlanu kodwa futhi anciphisa imvamisa yokufakwa esikhundleni kwezingxenye ezihambisanayo, anciphise izindleko zokugcinwa kwemishini ngo-40%. Imishini yokugaya ufulawa ephakathi nendawo ikhombisile ukuthi ngokumane ishintshe amaketanga okugaya asezingeni eliphezulu, angonga ama-yuan angu-80,000 kuya ku-100,000 ezindlekweni zokugcinwa kwemishini zonyaka futhi andise isikhathi sokwehla kwenani lemishini kusukela eminyakeni engu-8 kuya kwengu-12.

Ngaphezu kwalokho, ukuguquguquka kwamaketanga okugoqa kwenza kube lula ukulawula izindleko kwezolimo. Amaketanga okugoqa anezincazelo ezifanayo angasetshenziswa nemikhiqizo ehlukene namamodeli emishini yezolimo, okunciphisa ingcindezi yempahla esetshenziswayo emapulazini. Emapulazini asezindaweni ezikude, izingxenye ezisele ezinganele zivame ukuba yinselele enkulu ngemuva kokwehluleka kwemishini. Ukuguquguquka kwamaketanga okugoqa kuvumela amapulazi ukuthi agcine inani elincane kuphela lemininingwane ebalulekile yokusingatha ukulungiswa okuphuthumayo kwemishini ehlukahlukene, okunciphisa izindleko zempahla kanye nezindleko zokugcina.

IV. Ukukhuthaza Ukuthuthukiswa Kwemishini Yezolimo: Inhloso Eyisisekelo Yokusekela Intuthuko Yezolimo Eqhubekayo

Njengoba ezolimo zomhlaba wonke zishintshela emikhubeni eluhlaza, esebenza kahle, neqhubekayo, izidingo zezingxenye zokudlulisela emishinini emisha yezolimo ziya ngokuya ziba nzima. Ukuvela kobuchwepheshe bezintambo ezigoqekayo kunikeza ukwesekwa okuyisisekelo kokuthuthukiswa kwemishini yezolimo nokushayela izinguquko ezindleleni zokukhiqiza ezolimo.

Emkhakheni wemishini emisha yezolimo yamandla, imishini emisha efana namatrakta kagesi kanye nemishini yokunisela yelanga ibeka izidingo eziphakeme kakhulu emsindweni ophansi kanye nokusetshenziswa kwamandla aphansi ezinhlelweni zayo zokudlulisa. Ngokwenza ngcono isakhiwo sepuleti leketanga kanye nokusebenzisa igrisi yokugcoba ethule, amaketanga endabuko e-roller anganciphisa umsindo ube ngaphansi kwama-decibel angu-65 kanye nokusetshenziswa kwamandla ngo-5%, okwenza abe afanele izidingo zemishini emisha yezolimo yamandla. Umshini wokuvuna kagesi owakhiwe yinkampani ethile, ohlonyiswe ngeketanga le-roller elithule, awugcini nje ngokuhlangabezana nezindinganiso zomsindo zokusebenza kwezolimo kodwa futhi unciphisa ukusetshenziswa kwamandla, wandise isikhathi sokusebenza ngamahora angu-1.5 ngeshaja eyodwa, okuthuthukisa ukusebenza kahle kakhulu.

Emkhakheni wezolimo zemvelo, ukumelana nokugqwala kwamaketanga okugoqa kwenza kube lula ukusebenzisa imishini yezolimo enobungani nemvelo. Imishini yokufakelwa irayisi kanye nemishini yokuvikela izitshalo esetshenziswa emasimini erayisi ivezwa ezindaweni ezinomswakama nezinothuli isikhathi eside, lapho amaketanga avamile evame ukugqwala futhi ehluleka khona. Kodwa-ke, amaketanga okugoqa enziwe ngensimbi engagqwali noma anezimbozo ezingaphezulu angamelana nokugqwala kwe-acid ne-alkali kanye nokucwiliswa emanzini anodaka, okwandisa impilo yawo yenkonzo izikhathi ezingaphezu kwezimbili. Lokhu akugcini nje ngokunciphisa imfucuza ekhiqizwa ukushintshwa kwamaketanga kodwa futhi kunciphisa ukungcola kwenhlabathi namanzi okuvela ekusebenzeni kwemishini yezolimo, okuhambisana nentuthuko yezolimo zemvelo.

Ngaphezu kwalokho, ukwakheka kwe-modular kwamaketanga okugoqa kusiza ekuthuthukiseni okuhlakaniphile kwemishini yezolimo. Ngokuhlanganisa izinzwa ochungechungeni, amapharamitha anjengokucindezelwa kwesistimu yokudlulisa kanye nokushisa kungaqashwa ngesikhathi sangempela, kudluliswe le datha ohlelweni lokulawula oluhlakaniphile lwemishini, okuvumela ukulungiswa kokubikezela. Lapho kuvela izixwayiso zokuguguleka kwamaketanga, uhlelo lungaxwayisa abaqhubi ukuthi bashintshe uchungechunge, kugwenywe ukuphazamiseka kokukhiqiza okubangelwa ukwehluleka okungazelelwe. Lokhu kuhlanganiswa "kobuhlakani + ukudluliselwa okuthembekile" sekuyinto ebalulekile kwezolimo ezihlakaniphile.

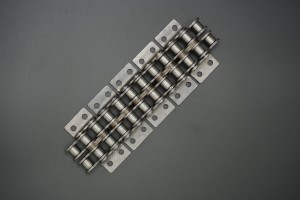

Indlela Yokukhetha: Ukuqaphela “Inani Elingabonakali” Lama-Roller Chains

Kwabasebenzi bezolimo, ukukhetha uchungechunge olufanele lwe-roller kuyinto edingekayo ukuze kuqashelwe inani lalo elingabonakali. Uma uthenga, gxila ezinkombeni ezintathu ezibalulekile: Okokuqala, “Izinto Nobuciko.” Khetha imikhiqizo eyenziwe ngezinsimbi ezinamandla aphezulu njenge-40Cr kanye ne-20Mn2, eziqiniswa nge-through-hardening kanye ne-roller carburizing. Okwesibili, “Ibanga Lokunemba.” Imishini yezolimo incoma ukusebenzisa amaketanga ane-ISO Grade 6 noma ngaphezulu ngokunemba ukuqinisekisa ukudluliselwa okuzinzile. Okwesithathu, “Ukuhambisana.” Khetha ububanzi be-pitch kanye ne-roller obuhambisana namandla, isivinini, kanye nendawo yokusebenza yemishini yezolimo. Ukwenza ngokwezifiso kuyatholakala uma kudingeka.

Ukugcinwa njalo nakho kubalulekile. Ngesikhathi sokusetshenziswa kwansuku zonke, hlanza uchungechunge lokungcola kanye nemfucumfucu ngokushesha bese ufaka amafutha akhethekile njalo ukuze uvimbele ukuguguleka okusheshayo okubangelwa ukungqubuzana okomile. Izinyathelo ezilula zokugcinwa zingandisa isikhathi sokuphila kwamaketanga ajikelezayo ngo-30% owengeziwe, okwandisa inani lawo elingabonakali.

Isiphetho: Inani Elingabonakali Lisekela Ikusasa Elisimeme

Amaketanga okugoqa awanakho ukuduma komshini wokuvuna noma ukukhanya kwezinhlelo ezihlakaniphile, kodwa angena ngokuthula kuzo zonke izici zomkhiqizo wezolimo. Aqinisekisa ukukhiqizwa okuqhubekayo, athuthukisa ukusebenza kahle, athuthukise izakhiwo zezindleko, futhi aqhubekisele phambili ukuthuthukiswa kwezolimo. Leli nani elingabonakali liyisisekelo sokusetshenziswa kwemishini yezolimo kanye nenjini engabonakali yokuthuthukiswa kwezolimo.

Isikhathi sokuthunyelwe: Septhemba 12-2025