Ungahlola futhi ufake kanjani amafutha ezintambo ze-roller njalo?

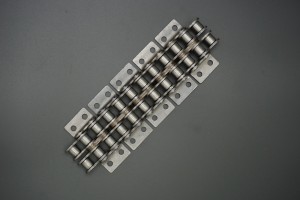

Ukugcotshwa kwamaketanga okugoqa kubalulekile ekugcineni ukusebenza kwawo nokwandisa isikhathi sawo sokusebenza. Nazi izinyathelo eziningiliziwe namathiphu okuhlola njalo nokufaka esikhundleni samafutha amaketanga okugoqa.

1. Hlola njalo isimo sokuthambisa

Ukuhlolwa kokubukeka: Ngaphambi kokuqala umshini nsuku zonke, qala uhlole ukubonakala kwe-roller chain coupling ukuqinisekisa ukuthi azikho izimpawu zomonakalo, ukuguquguquka noma ukugqwala. Ngesikhathi esifanayo, naka ukucindezeleka kweketanga ukuqinisekisa ukuthi aliqinile kakhulu ukwandisa ukuguguleka noma ukukhululeka kakhulu ukubangela ukweqa kweketanga.

Isimo sokugcotshwa: Hlola izindawo zokugcotshwa ukuqinisekisa ukuthi igrisi yanele futhi ihlanzekile. Faka inani elifanele legrisi ku-roller chain njalo ukuze unciphise ukungqubuzana futhi unciphise ukulahlekelwa. Qaphela ukuthi ukukhetha igrisi kumele kuhambisane nezimo zokusebenza futhi kugweme ukuxuba izinhlobo ezahlukene.

Umsindo wokusebenza: Ngemva kokuqala imishini, lalela ngokucophelela umsindo wokusebenza we-roller chain coupling. Umsindo ongajwayelekile uvame ukuba uphawu lwephutha, njengezinkinga ze-chain kanye ne-sprocket meshing, umonakalo wamabhere, njll., okudingeka uhlolwe ngesikhathi.

2. Ukuhlanza nokuhlanza

Iketanga eligoqekayo kufanele lihlanzwe futhi lihlanzwe njalo, futhi umphumela wokugcoba kufanele uhlolwe njalo. Hlanza iketanga ngensipho ethambile kanye nebhulashi elithambile ukuze ususe uthuli namafutha amadala. Lesi sinyathelo sibalulekile ukuqinisekisa ukuthi amafutha asatshalaliswa ngokulinganayo kuzo zonke izingxenye zeketanga.

3. Hlola umphumela wokugcoba

Ngemva kokuhlanza, hlola umphumela wokugcoba weketanga. Uma indawo yokungqubuzana insundu noma insundu emnyama, lokhu kuvame ukusho ukuthi uwoyela awunele futhi ukugcotshwa akukuhle. Kulesi simo, amafutha kudingeka ashintshwe.

4. Khetha amafutha afanele

Kubalulekile ukukhetha ugrisi ofanele izimo zokusebenza. Ugrisi wokulwa nokugqwala osetshenziswa kwamanye amaketanga okugoqa unemiphumela yokulwa nokugqwala kanye nokugcoba futhi ungumkhiqizo wokugcoba obiza kakhulu. Ungavimbela ngempumelelo ukungqubuzana ekuqaleni kokusebenza futhi uqinisekise ukuhlangana kweketanga kanye nogrisi ukuze kuthuthukiswe ukumelana nokungqubuzana.

5. Buyisela amafutha

Ukwengeza isikhundla samafutha: Ukunwebeka kokungqubuzana kwe-roller chain kuvame ukwenzeka phakathi kwephini le-chain kanye ne-bushing, ngakho-ke engeza uwoyela kulesi sikhundla. Uma ungeza uwoyela wokugcoba, sicela ungeze uwoyela phakathi kwepuleti le-chain yangaphandle kanye nepuleti le-chain yangaphakathi ohlangothini oluxegayo lwe-roller chain. Ngesikhathi esifanayo, uwoyela udinga ukufakwa phakathi kwe-sleeve ne-roller.

Indlela yokugcwalisa uphethiloli: Kuye ngendawo esetshenziswayo, izindlela ezahlukene zokugcwalisa zingakhethwa, okuhlanganisa ukufaka uphethiloli ngesandla, ukugcoba ngebhavu lamafutha, ukugcoba nge-splash kanye nokugcoba ngepompo kawoyela ephoqelelwe. Indlela ngayinye inenani layo elithile lokugcwalisa uphethiloli kanye nezidingo zemvamisa.

Umjikelezo wokufaka esikhundleni: Nquma umjikelezo wokufaka esikhundleni samafutha ngokusekelwe ezincomweni zomkhiqizi wemishini kanye nemibandela yokusetshenziswa. Ngokuvamile, gcwalisa uphethiloli kanye njalo emahoreni angu-8 noma ngaphezulu.

6. Ukuqeqeshwa kobungcweti kanye nokuxilongwa kwamaphutha

Nikeza ukuqeqeshwa kobungcweti kwabasebenzi kanye nabasebenzi bokulungisa ukuze bathuthukise ikhono labo lokubona nokubhekana nokusebenza kokuxhumanisa i-roller chain, amaphutha, kanye nezimo eziphuthumayo. Lapho behlangabezana namaphutha ayinkimbinkimbi, ochwepheshe abangochwepheshe kufanele bamenywe ukuzoxilonga, basebenzise amathuluzi ukuthola ngokushesha imbangela yenkinga, futhi bakhe uhlelo lokulungisa olungokwesayensi nolunengqondo olusekelwe emiphumeleni yokuxilonga.

7. Ukuqopha nokuhlaziya

Misa ifayela eliphelele lerekhodi lokulungisa, urekhode isikhathi, okuqukethwe, izingxenye ezithathelwe indawo kanye nemiphumela yokulungisa ngakunye ngokuningiliziwe, bese unikeza inkomba eqinile yokulungisa okulandelayo.

Ngokulandela izinyathelo ezingenhla, ungaqinisekisa ukuthi igrisi ye-roller chain ihlolwa kahle futhi ithathelwe indawo, ngaleyo ndlela yandise impilo yesevisi ye-chain futhi igcine ukusebenza kwayo okuhle kakhulu.

Ungawuhlola kanjani umphumela wamafutha? Yiziphi izinkomba ezingasetshenziswa njengereferensi?

Uma uhlola umphumela wamafutha, ungabheka izinkomba ezilandelayo ezibalulekile:

Ukusebenza kokulwa nokugqwala: Hlola ikhono lokulwa nokugqwala kwamafutha ezinsimbini ngaphansi kwezimo ezahlukene zemvelo

Ukusebenza kwezinga lokushisa eliphansi: Hlola ukugeleza kanye nokumpompa kwamafutha endaweni enezinga lokushisa eliphansi

Ukusebenza kwezinga lokushisa eliphezulu: Hlola ukuzinza nokusebenza kokuthambisa kwamafutha endaweni eshisa kakhulu

Ukumelana namanzi: Hlola ukuthi amafutha angagezwa ngamanzi futhi angasebenzi kahle yini endaweni enomswakama.

Ukuhlolwa kwesimo sokusebenza okulingisiwe: Lingisa izimo zokusebenza zangempela (njengokushisa, ingcindezi, isivinini, njll.) elabhorethri bese wenza ukuhlolwa kokusebenza kwesikhathi eside

Ukuhlolwa kokuguga: Lingisa ukuguga kwamafutha ngesikhathi sokusetshenziswa isikhathi eside ukuze uhlole impilo yawo yenkonzo kanye nomjikelezo wokushintshwa kwawo

Ukuhlolwa kwensimu kanye nempendulo: Faka amafutha emishinini yangempela, wenze izivivinyo isikhathi esithile, bese uqoqa idatha yokusebenza kanye nempendulo yomsebenzisi

Ukulawulwa kwekhwalithi kanye nesitifiketi: Sebenzisa ngokuqinile amazinga okulawula ikhwalithi ngesikhathi senqubo yokukhiqiza ukuqinisekisa ukuvumelana nokuqina kweqoqo ngalinye lamafutha, futhi wenze isitifiketi nokuhlolwa komuntu wesithathu (njenge-ISO, i-ASTM kanye nezinye izindinganiso) ngokuya ngezindinganiso zemboni kanye nezidingo zamakhasimende.

I-Thixotropy: I-thixotropy yamafutha isho ukuthi ithamba kancane kancane lapho kusetshenziswa amandla angaphandle, futhi i-viscosity iyancipha, kodwa ingalulama ngemva kokuma. Izici zokuvumelana okuyinkimbinkimbi

Ukuthamba: Ukuthamba kwamafutha kuyinkomba yokuthamba kwawo, ngokuvamile kuvezwa njengokuthamba okubonakalayo noma ukuthamba okufanayo, futhi izinga lokushisa kanye nesivinini sokucheba kumele kuchazwe.

Umkhawulo wamandla: Umkhawulo wamandla wamafutha ubhekisela ekucindezelekeni okuncane kokusika okudingekayo ukuze isampula iqale ukugeleza

Ukugeleza kokushisa okuphansi: Esinye sezibonakaliso ezibalulekile zokulinganisa ukusebenza kokushisa okuphansi kwamafutha yi-torque yokushisa okuphansi, okungukuthi, izinga lapho amafutha evimbela khona ukujikeleza kwe-bearing yokugeleza okuphansi emazingeni okushisa aphansi

Indawo yokuwa: Izinga lokushisa eliphansi kakhulu lapho igrisi ifinyelela khona uketshezi oluthile ngaphansi kwezimo ezithile libizwa ngokuthi indawo yokuwa, okusiza ukuhlonza uhlobo lwegrisi nokulinganisa izinga lokushisa lokusebenza eliphezulu.

Ukukhishwa Kokuhwamuka Komoya: Ukuguquguquka kwamafutha kubonisa izinga lokuhwamuka kwamafutha lapho amafutha esetshenziswa isikhathi eside ngaphansi kwezimo zokushisa eziphakeme

Ukuzinza kwe-Colloid: Ukuzinza kwe-colloidal kwegrisi kubhekisela ekhonweni layo lokugcina isakhiwo se-colloidal esizinzile ekushiseni okuthile kanye nengcindezi ukuvimbela uwoyela wokugcoba ukuthi ungangeni kugrisi.

Ukuqina kwe-oxidation: Ukuqina kwe-oxidation kwamafutha kubhekisela ekhonweni lawo lokumelana nemiphumela yokushisa nomoya-mpilo ngesikhathi sokugcina isikhathi eside noma ukusetshenziswa isikhathi eside emazingeni okushisa aphezulu, kanye nokugcina izakhiwo zawo ngaphandle kwezinguquko ezihlala njalo.

Ngalezi zinkomba, ukusebenza kanye nomphumela wamafutha kungahlolwa ngokuphelele ukuqinisekisa ukuthi amafutha akhethiwe angahlangabezana nezidingo zezicelo ezithile.

Isikhathi sokuthunyelwe: Disemba-09-2024