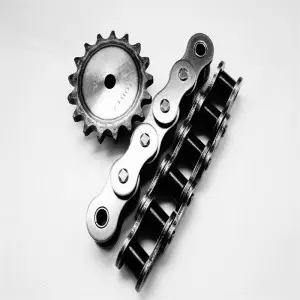

Ubuchwepheshe bokwelapha ukushisa bunomthelela omkhulu ekhwalithini yangaphakathi yezingxenye zamaketanga, ikakhulukazi amaketanga esithuthuthu. Ngakho-ke, ukuze kukhiqizwe amaketanga esithuthuthu asezingeni eliphezulu, kudingeka ubuchwepheshe obuthuthukisiwe bokwelapha ukushisa kanye nemishini.

Ngenxa yegebe phakathi kwabakhiqizi basekhaya nabangaphandle maqondana nokuqonda, ukulawulwa kwendawo kanye nezidingo zobuchwepheshe zekhwalithi yochungechunge lwesithuthuthu, kunomehluko enqubweni yokwakhiwa, ukuthuthukiswa kanye nokukhiqiza ubuchwepheshe bokwelashwa kokushisa kwezingxenye zochungechunge.

(1) Ubuchwepheshe bokwelapha ukushisa kanye nemishini esetshenziswa abakhiqizi basekhaya. Imishini yokwelapha ukushisa embonini yeketanga yezwe lami isalele emuva kweyamazwe athuthukile kwezimboni. Ikakhulukazi, izitofu zebhande le-mesh zasekhaya zinezinkinga eziningi ezifana nesakhiwo, ukuthembeka kanye nokuqina.

Amapuleti e-chain angaphakathi nangaphandle enziwe ngamapuleti ensimbi angu-40Mn kanye no-45Mn, futhi izinto ikakhulukazi zineziphambeko ezifana nokususwa kwe-carburization kanye nemifantu. Ukucima nokushisa kusebenzisa isithando sebhande esivamile se-mesh ngaphandle kokwelashwa kokuvuselelwa kabusha, okuholela engqimbeni yokususwa kwe-carburization ngokweqile. Amaphini, imikhono nama-roller ashintshwa futhi acinywe, ukujula kokuqina okusebenzayo kokucima kungu-0.3-0.6mm, kanti ubulukhuni bomphezulu bungu-≥82HRA. Nakuba isithando se-roller sisetshenziselwa ukukhiqizwa okuguquguqukayo kanye nokusetshenziswa okuphezulu kwemishini, ukusetha kwamapharamitha enqubo Izilungiselelo nezinguquko kudingeka zenziwe ochwepheshe, futhi enkambisweni yokukhiqiza, lawa manani epharamitha asethwe ngesandla awakwazi ukulungiswa ngokuzenzakalelayo ngokushintsha okusheshayo komkhathi, futhi ikhwalithi yokwelashwa kokushisa isancike kakhulu kochwepheshe bendawo (izisebenzi zobuchwepheshe). Izinga lobuchwepheshe liphansi futhi ukuphindaphindwa kwekhwalithi kubi. Uma kucatshangelwa umkhiqizo, imininingwane kanye nezindleko zokukhiqiza, njll., lesi simo kunzima ukusishintsha isikhashana.

(2) Ubuchwepheshe bokwelapha ukushisa kanye nemishini esetshenziswa abakhiqizi bangaphandle. Izitofu zebhande le-mesh eziqhubekayo noma imigqa yokukhiqiza ukwelashwa kokushisa kweketanga elibunjiwe isetshenziswa kabanzi kwamanye amazwe. Ubuchwepheshe bokulawula umoya buvuthiwe impela. Asikho isidingo sokuba ochwepheshe bakhe inqubo, futhi amanani afanele epharamitha angalungiswa nganoma yisiphi isikhathi ngokuya ngezinguquko ezisheshayo emkhathini esithandweni; ukuze kugxilwe ungqimba olufakwe i-carburized, isimo sokusatshalaliswa kobunzima, umoya kanye nokushisa kungalawulwa ngokuzenzakalelayo ngaphandle kokulungiswa ngesandla. Inani lokuguquguquka kokugxilwa kwekhabhoni lingalawulwa ngaphakathi kobubanzi obungu-≤0.05%, ukuguquguquka kwenani lobunzima kungalawulwa ngaphakathi kobubanzi obungu-1HRA, futhi izinga lokushisa lingalawulwa ngokuqinile ngaphakathi kobubanzi obungu-± Phakathi kobubanzi obungu-0.5 kuya ku-±1℃.

Ngaphezu kwekhwalithi ezinzile yokucima nokulungisa ipuleti leketanga langaphakathi nelangaphandle, iphinde ibe nokusebenza kahle kokukhiqiza okuphezulu. Ngesikhathi sokufaka i-carburing nokucima i-pin shaft, i-sleeve ne-roller, ushintsho lwejika lokusabalalisa lokuhlushwa lubalwa njalo ngokuya ngenani langempela lesampula lokushisa kwesithando kanye namandla e-carbon, futhi inani elibekiwe lamapharamitha enqubo liyalungiswa futhi lenziwe ngcono nganoma yisiphi isikhathi ukuqinisekisa ukuthi ungqimba lwe-carburing Ikhwalithi yangaphakathi iyalawulwa.

Ngamafuphi, kukhona igebe elikhulu phakathi kwezinga lobuchwepheshe bokwelashwa kokushisa kwezingxenye zesithuthuthu sezwe lami kanye nezinkampani zakwamanye amazwe, ikakhulukazi ngoba uhlelo lokulawula ikhwalithi kanye nesiqinisekiso aluqinile ngokwanele, futhi lusasele ngemuva kwamazwe athuthukile, ikakhulukazi umehluko kubuchwepheshe bokwelashwa kobuso ngemva kokwelashwa kokushisa. Amasu okufaka imibala alula, asebenzayo futhi angangcolisi emazingeni okushisa ahlukene noma ukugcina umbala wokuqala angasetshenziswa njengokukhetha kokuqala.

Isikhathi sokuthunyelwe: Septhemba-08-2023