Ukuqhathaniswa Kokunemba Kokudlulisela Phakathi Kwezintambo Ezigoqekayo Nezintambo Ezinamazinyo

I. I-Logic Eyisisekelo Yokunemba Kokudlulisela: Umehluko Wesakhiwo Unquma Umkhawulo Ophezulu Wokusebenza

1. I-Bottleneck Yokunemba Kwezintambo Ezigoqekayo: Umphumela We-Polygonal kanye Nokugqokwa Okungafani

Amaketanga e-roller aqukethe ama-roller, ama-bushing, ama-pin, nama-chain plate. Ngesikhathi sokufaka i-meshing, amandla adluliselwa ngokuxhumana kwephuzu phakathi kwama-roller namazinyo e-sprocket. Amaphutha awo okunemba okuyinhloko avela kumaphuzu amabili: **Umphumela we-Polygonal:** Iketanga lakha isakhiwo esivamile se-polygonal esizungeze i-sprocket. Uma i-pitch P inkulu futhi amazinyo e-sprocket eba mancane, kulapho ukuguquguquka kwesivinini okusheshayo kuba kubi kakhulu (ifomula: v=πd₁n₁/60×1000, lapho i-d₁ ingububanzi bendilinga ye-sprocket pitch), okuholela esilinganisweni sokudlulisa esingazinzile. **Ukuguga okungalingani:** Ngemva kokuguga kwe-hinge, i-outer link pitch iyanda kakhulu ngenkathi i-inner link igcina usayizi wayo wokuqala, idala umehluko we-pitch osheshisa ukubola kokunemba.

2. Izinzuzo ezinembile zamaketanga anamazinyo: I-Involute meshing kanye nokwelulwa okufanayo. Amaketanga anamazinyo (aziwa nangokuthi amaketanga athule) aboshwe ngama-hinge kusuka kuma-staggered toothed chain plates. I-line contact meshing itholakala ngephrofayili yamazinyo e-chain plate kanye nephrofayili yamazinyo e-involute ye-sprocket: **Izici ze-multi-tooth meshing:** Isilinganiso sokugqagqana sifinyelela ku-2-3 (amaketanga e-roller kuphela…). 1.2-1.5), sisabalalisa umthwalo ngenkathi kuqinisekiswa ukuqhubeka kokudluliselwa. Idizayini yokuguguleka efanayo: Ukunwebeka okuphelele kwesixhumanisi ngasinye seketanga kuyahambisana ngemva kokuguguleka, ngaphandle kokuphambuka kwephimbo lendawo, okuholela ekugcinweni kokunemba okungcono kwesikhathi eside. Isakhiwo somhlahlandlela esilungiselelwe: Idizayini yomhlahlandlela wangaphakathi igwema ukunyakaza okuseceleni, kanye nokulawulwa kwamaphutha okufana phakathi kwama-shaft amabili kunembile kakhulu.

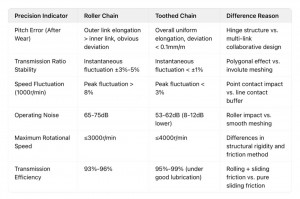

II. Ukuqhathaniswa Okulinganiselwe Kwezinkomba Zokunemba Kokudlulisela Okuyinhloko

III. Izici Ezibalulekile Zangaphandle Ezithinta Ukunemba Kokudlulisela

1. Ukuzwela Ekuqondeni Kokufakwa: Amaketanga anamazinyo anezidingo eziphakeme kakhulu zokufana kwama-shaft amabili (iphutha ≤ 0.3mm/m), ngaphandle kwalokho kuzokwandisa ukuguguleka kwepuleti leketanga futhi kubangele ukwehla okukhulu kokunemba. Amaketanga e-roller avumela amaphutha amakhulu okufakwa (≤ 0.5mm/m), avumelane nezimo zokubeka izinto ezinzima ngaphansi kwezimo zokusebenza ezinzima.

2. Ithonya Lomthwalo Nesivinini: Umthwalo osindayo onesivinini esiphansi (<500rpm): Umehluko wokunemba phakathi kwalawa amabili uncishisiwe, futhi amaketanga e-roller ayonga kakhulu ngenxa yenzuzo yawo yezindleko. Ukunemba kwesivinini esiphezulu (>2000rpm): Inzuzo yokucindezela umphumela we-polygon yamaketanga anamazinyo iyabonakala, futhi izinga lokubola kokunemba liyi-1/3 kuphela lamaketanga e-roller.

3. Ukubaluleka Kokugcoba Nokunakekela Ekulungiseni Okunembile: Amaketanga e-roller abhekana nokuguguleka okusheshayo okuphindwe ka-3-5 uma engenawo amafutha, futhi iphutha le-pitch landa kakhulu. Amaketanga anamazinyo adinga ukuhlanzwa njalo nokugcoba ukuze kugcinwe ukunemba kwezindawo zokungqubuzana ezishelelayo, okuholela ezindleleni zokulungisa eziphakeme kunemaketanga e-roller.

IV. Umhlahlandlela Wokukhetha Osekelwe Ezimweni: Izidingo Zokunemba Zithatha Ibanga Elibalulekile Kunokucatshangelwa Kwezindleko

1. Izimo Zokusebenzisa Uchungechunge Olunamazinyo:

Imishini yokunemba ngesivinini esiphezulu: Ukudluliselwa kwesikhathi senjini, ithuluzi lomshini lokunemba i-spindle drive (isivinini > 3000 r/min)

Izindawo ezinomsindo ophansi: Imishini yendwangu, amadivayisi ezokwelapha (isidingo somsindo < 60dB)

Ukudluliselwa okubushelelezi okusindayo: Imishini yokumba, imishini yensimbi (i-torque > 1000 N·m)

2. Izimo Zokusebenzisa I-Roller Chain:

Imishini ejwayelekile: Imishini yezolimo, imigqa yokuhambisa impahla (isivinini esiphansi, umthwalo osindayo, isidingo sokunemba ±5%)

Izindawo ezilukhuni: Izimo zothuli/ezinomswakama (isakhiwo esilula, ikhono eliqinile lokulwa nokungcola)

Amaphrojekthi athinta izindleko: Izindleko zeketanga eligoqekayo elinomugqa owodwa zincane kakhulu kunezeketanga elinamazinyo elinezincazelo ezifanayo. 40%-60%

V. Isifinyezo: Ubuciko Bokulinganisela Ukunemba Nokusebenza

Ingqikithi yokunemba kokudlulisela ingumphumela ophelele wokwakheka kwesakhiwo, ukucubungula izinto, kanye nokuzivumelanisa nezimo zokusebenza: Amaketanga anamazinyo afinyelela ukunemba okuphezulu kanye nokuqina okuphezulu ngezakhiwo eziyinkimbinkimbi, kodwa athwala izindleko zokukhiqiza eziphakeme kanye nezidingo zokufaka; Amaketanga anama-roller adela ukunemba okuthile ngenxa yokuguquguquka, izindleko eziphansi, kanye nokulula kokugcinwa. Lapho ukhetha imodeli, izidingo eziyinhloko kufanele zibekwe phambili: Lapho isidingo sephutha lesilinganiso sokudlulisela singu-<±1%, ijubane lingu->2000 r/min, noma ukulawula umsindo kuqinile, amaketanga anamazinyo ayisisombululo esifanele; uma izimo zokusebenza zinzima, isabelomali sinqunyelwe, futhi ukubekezelelana kokunemba kuphezulu, amaketanga anama-roller ahlala eyisinqumo esithembekile embonini.

Isikhathi sokuthunyelwe: Novemba-24-2025